80KW Potable Pipeline Induction Preheater

|

| Full air-cooled Induction Heating Machine Parameters |

Model | SF-F-40KW | SF-F-60KW | SF-F-80KW | SF-F-120KW |

Input Voltage | 3*380V,50/60Hz |

Input Current | 1-60A | 1-90A | 1-120A | 1-180A |

Input Power | 1-40KW | 1-60KW | 1-80KW | 1-120KW |

Oscillation Frequency | 5-20KHZ | 10-40KHZ | 10-40KHZ | 10-40KHZ |

Heating Temperature | Max:900℃;Heating speed:5-100℃/min |

Heating Pipeline Size | 50-750mm | 50-850mm | 50-950mm | 50-1100mm |

Size (mm) | 600*350*550mm | 400*350*950mm | 680*400*770mm | 780*500* 1060 |

Weight (KG) | 68kg | 88kg | 106kg | 128KG |

Induction coil Legth | 5-8m | 8-10m | 10-14m | 10-20m |

Optional Parts | Induction Coil | Insulation Blanket | K type thermocouple | High temperature adhesive tape |

Connection Cable | Thermocouple | Temperature recorder | Asbestos board |

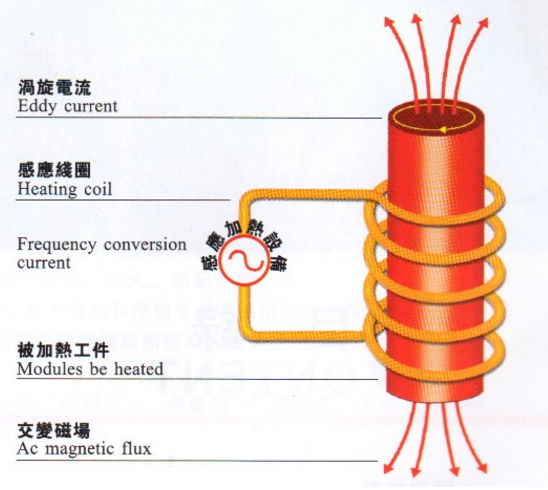

1. Full air-cooled electromagnetic heater technology principle:

The electromagnetic heater converts 200V or 380V 50/60HZ AC power into 15-20KHZ high frequency power. When the high-frequency current passes through the coil, a high-speed alternating magnetic field is generated, so that the metal material in the magnetic field generates eddy current by cutting the alternating magnetic field lines, and the eddy current causes the iron atoms in the metal to move at high speed and irregularly, collide with each other and generate heat energy, and then generate heat energy. It has the effect of heating the items.

2. Main Characteristic:

Full air-cooled model of special structure (F-series)

1) The main power unit and output transformer adopt a full air cooling structure.

2) Generally, no need to use the water to cool the induction coil, in special cases (such as high current density), only the induction coil is required to connect the water.

3) Eliminate the trouble of waterway installation and save investment costs for clients.

4) It is especially suitable for workplaces that are difficult to reach the waterways, such as the field and large-scale movement circumstances.

5) Complete fault protection functions, such as water shortage, overheating, input overvoltage, undervoltage, phase loss, overcurrent, output overvoltage, short circuit, etc., all displayed in text form.

6) Friendly human-machine interface, the customer can set the data through the touch screen or by tapping the button.

3. Advantages of the air-cooled induction heating machine

(1) The main control cabinet of this equipment adopts air cooling, eliminates water cooling, does not cause water blockage, structural water leakage, water pipe aging and other failures. Greatly improve the stability of the equipment.

(2) The user does not need to build a pool, cooling tower, and no waterway installation, which greatly saves users' investment.

(3) A high power factor has low pollution to the grid.

(4) This equipment has a comprehensive protection circuit. Such as voltage, current, etc., to ensure that the equipment works properly.

(5) The heating speed of the equipment is fast, the production efficiency is high, and it is easy to use with other equipment.

4. The significant benefits of full air-cooled induction heating equipment to the manufacturer:

a. Statistics show that 70-80% of water-cooled induction heating equipment mainly comes from water gambling, pollution, scaling, water pipe aging, insufficient water pressure, too much moisture, water leakage, etc. The full air-cooling equipment has no such problems at all;

b. Reduce the user's preparation workload. Users do not need to build a pool, install a cooling tower, etc., and work cumbersomely;

c. Reduce investment in user waterways.

d. There is no special requirement for the use environment, and it is suitable for field and mountain work.

5. Application of full air-cooled induction heating equipment:

Oil industry | Chemical Industry | Other industry |

Oil pipeline Oil well drill pipe Wellhead valve Oil storage tank Dryer drain | 1) Carbonization 2) Molding 3) Hot pressing 4) Pipe heating, heat tracing, thermal preheating, constant temperature control heating 5) Improve fluid (vapor-liquid powder characteristics) 6)Reactor heating, thermal preheating, constant temperature, precise heating control | 1. Film blowing machine 2.Injection molding machine 3. Drawing machine 4. Granulator 5. Extruder for rubber 6. Casting machine 7. Cable production extruder 8.Optical fiber number film machine 9. Extruder | Gear production and bearing assembly (inductive heating principle is used to inductively heat and assemble parts such as bearing sleeves, gears, coupling ring diameter rings, etc. to make them expand thermally) Composite pipe production Tight fit processing Surface treatment, etc. | 1.Heating and insulation of various media lSurface treatment (spray drying, etc.) 2. Salt bath furnace heating Dry Disinfection and sterilization Pollutant heating Waste recycling, purification Superheated steam production Pipe cleaning |

Company Profiles:

Sinfor is specialized in researching and manufacturing of solid-state medium to ultrahigh frequency induction heating equipment and systems. our company was established in 2000 and is privately held. Precision induction heating solutions are our specialty. Use induction heating to improve the efficiency for industrial heating process. That are used for application such as brazing. annealing,hardening,forging, melting, shrink fitting etc.

Our induction heating machine are Available from 8kw to 1500kw deliverable output power with 0.5KHZ to1.1MHZ operating frequency range. All our products are divided into four major series according to the frequency:

Medium frequency series (abbr. MF series):0.2-10KHZ

High frequency series (abbr. HF series):30-100KHZ

Super-audio frequency series (abbr. SF series):10-40KHZ

Audio frequency series (abbr. SF-S series):5-20KHZ

Ultrahigh frequency series (abbr. UF series):100-1100KHZ

Sinfor is sincere in cooperation with people from all walks of life to create jointly great success.

Our theme: Energy saving, environmental protection, safety and intelligence.

Our aim: Working hand in hand to create great achievements.

Our vision: Touch China with quality, touch the world with credit.

Our value: Strives for the survival by the integrity, to innovate strives for the development.

R&D philosophy: Our "intention" is to save customers' worry.

Production philosophy: Our "carefulness" is for the "reassurance" of customers.

Service concept: Our "patience" is for the "comfort" of customers.

Foshan Sinfor Electro-Machanical Equipment Co., Ltd.

Building 1, No. 7, Bo'ai East Road, Area B, Shishan Industrial Park, Nanhai District, Foshan City,Guangdong Province, China,528000

Tel: +86 13302801519

FAX: +86 0757-85576875

Whatsapp: +86 13302801519

Skype: kate-cujinyuan

Email: Kate@sinfor198.com

Website:www.sinfor198.cn / www.sinfor198.com

Application video: https://youtu.be/UjyGRdZLwX4